Process Development and Supply of Clinical API

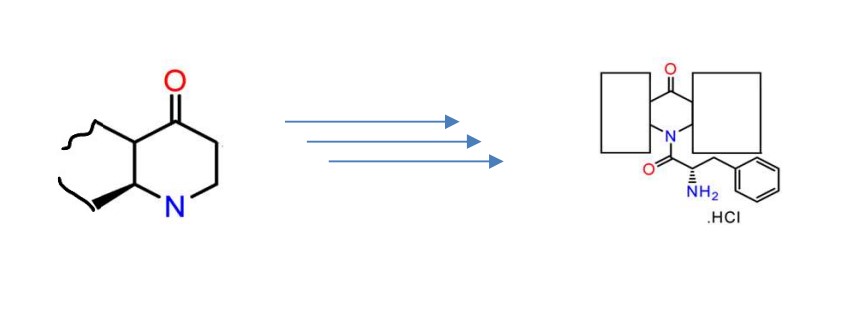

Scope:

Process Development and initial supply of 3X1Kg of API. 25 kg of GMP material after Process Optimization and 200 kg commercial production after plant validation.

Complexity:

Route involves Pyrophoric reagents and the KSM had stability issues leading to formation of Impurities during shipping. N-2 material has stability issues too. Controlling these impurities across the stages was very challenging.

Quality & Yield:

API was a chiral molecule & the final purity expectation was over 98% & 99% ee.

Accomplishment:

Shilpa made KSM inhouse and consumed immediately, Developed a process using N-2 Material

crude directly for next conversion.

Shilpa delivered 3*1kg of API successfully, remaining work is on going.